Biocompatibile coating in blood contacting materials

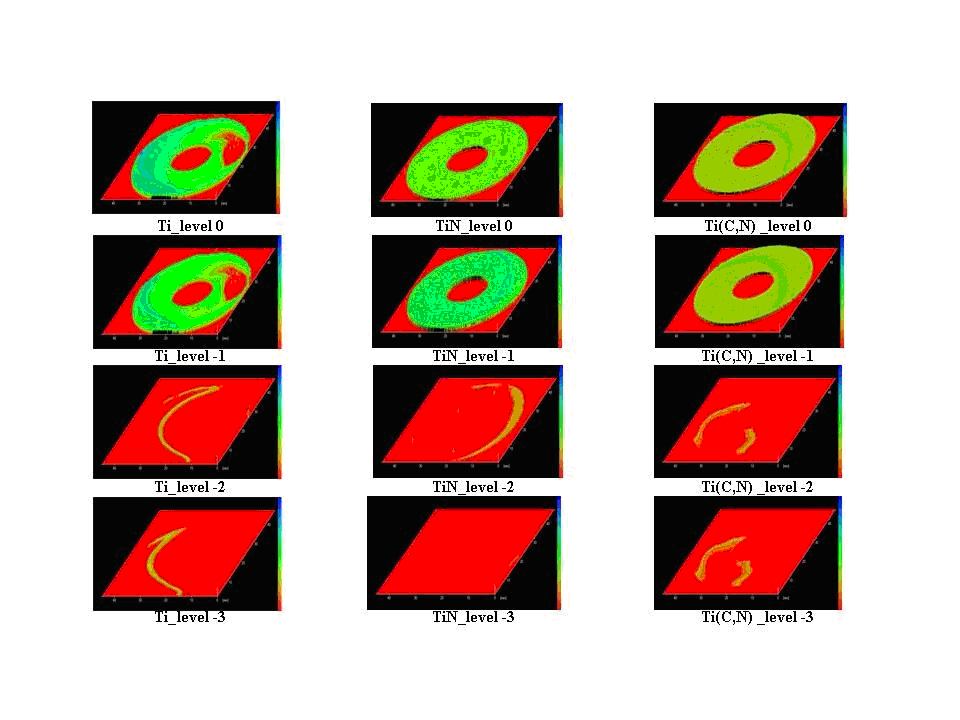

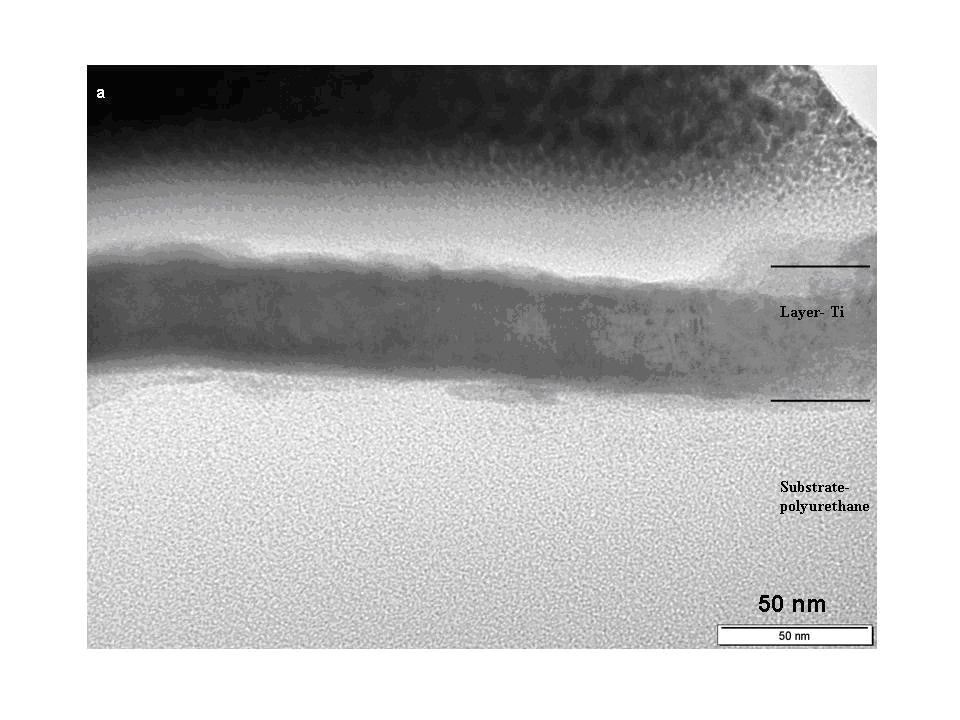

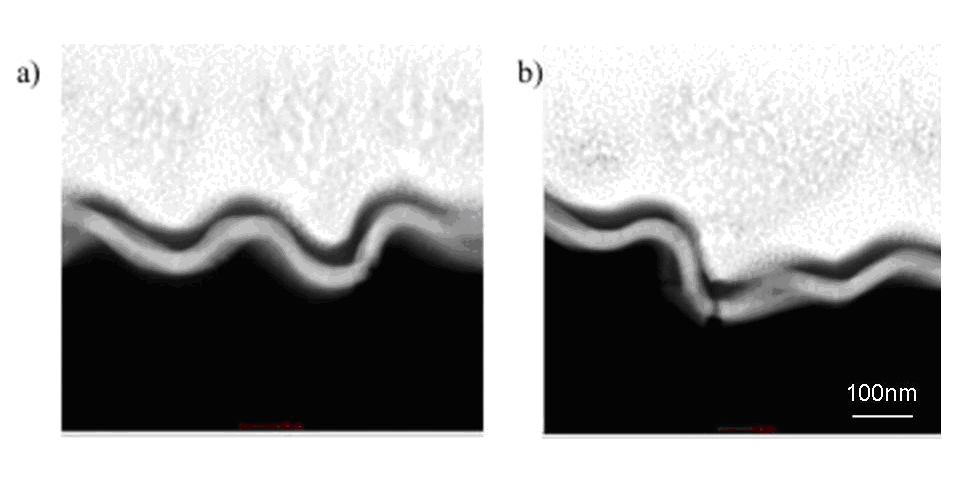

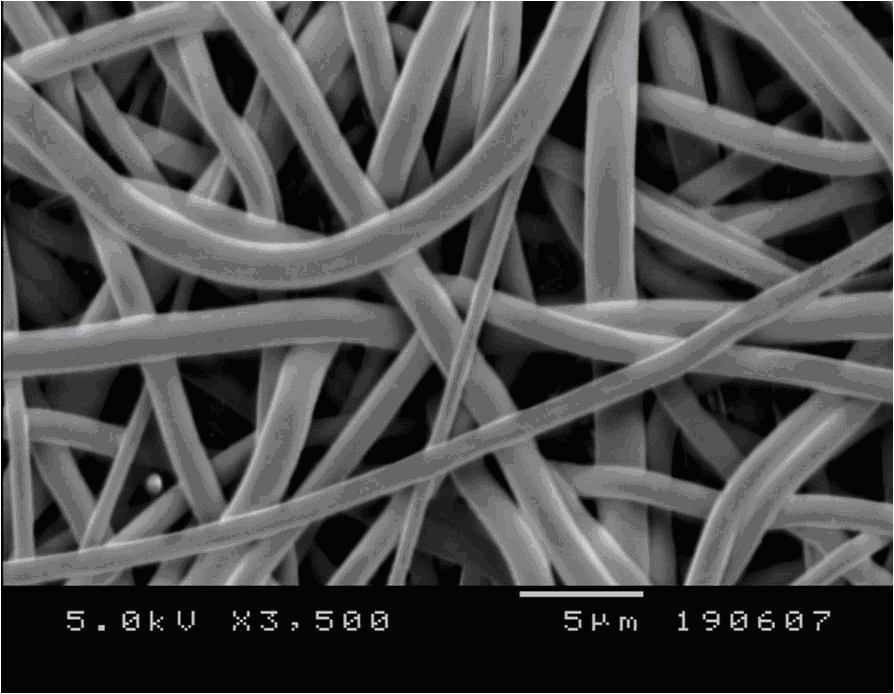

BIOMATERIALSThe bulk and surface properties of biomaterials used for medical implants have been shown to directly influence, and in some cases, control the dynamic interactions that take place at the tissue implant interface. These interactions are included in the concept of compatibility, which should be viewed as a bidirectional process between the implanted materials and the host environment that is ongoing through the in vivo lifetime of devices. Currently, considerable effort is directed towards the development of engineered surfaces that could elicit rapid and highly precise reactions with cells and proteins, tailored to specific applications. A development of novel, low thrombogenic materials is of central importance. Titanium nitride (TiN) is expected as a perspective biomaterial, however, it is currently observed that carbide (DLC diamond like carbide or PLC polymer like carbon)) and carbonitrides Ti(C,N) coatings become popular. Before they being applied it has to be evaluated and meet particular requirements depending on the proposed location in the body. Biomaterials such as mentioned before i.e.: Ti, stoichiometric TiN, titanium carbo-nitrade (Ti(C,N) and DLC, PLC seem to be good candidates for future blood-contact applications. These materials could be deposited as thin films by PVD (physical vapour deposition) or CVD (chemical vapour deposition) methods and subjected to examine the influence of the deposited material on the cell behaviour. Much attention is put to the diagnostics of the deposited coating in order to establish the optimal technological parameters from the physicochemical and biological point of view. The kinetics energy of the evaporated particles is selected to form a gradient structure and it is controlled by an application of a variation of different reactive and non-reactive atmospheres during the deposition. The purpose of this treatment is to improve adhesion by building a bridge between the real ceramic coating and the substrate. The conventional as well as advanced diagnostic methods, like X-ray diffraction (XRD), scanning (SEM) and transmission electron microscopy (TEM), high resolution transmission electron microscopy (HREM), acoustic scanning microscopy (ASM) are used to reveal the microstructure architecture (Fig.1-4).

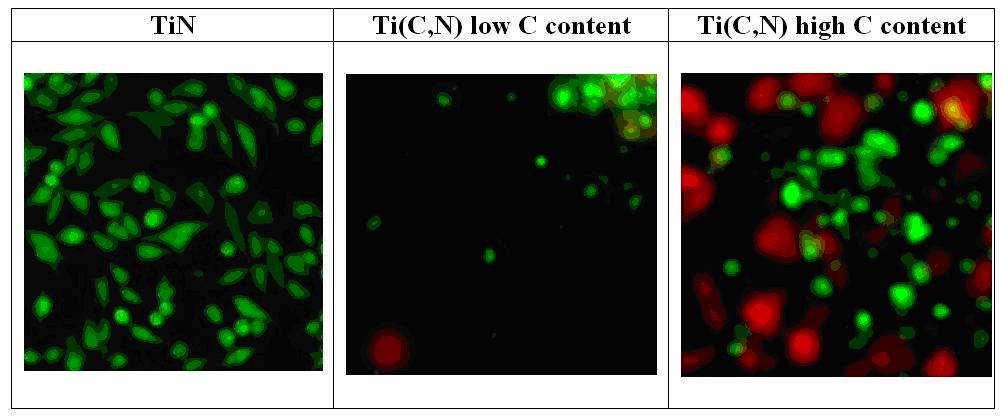

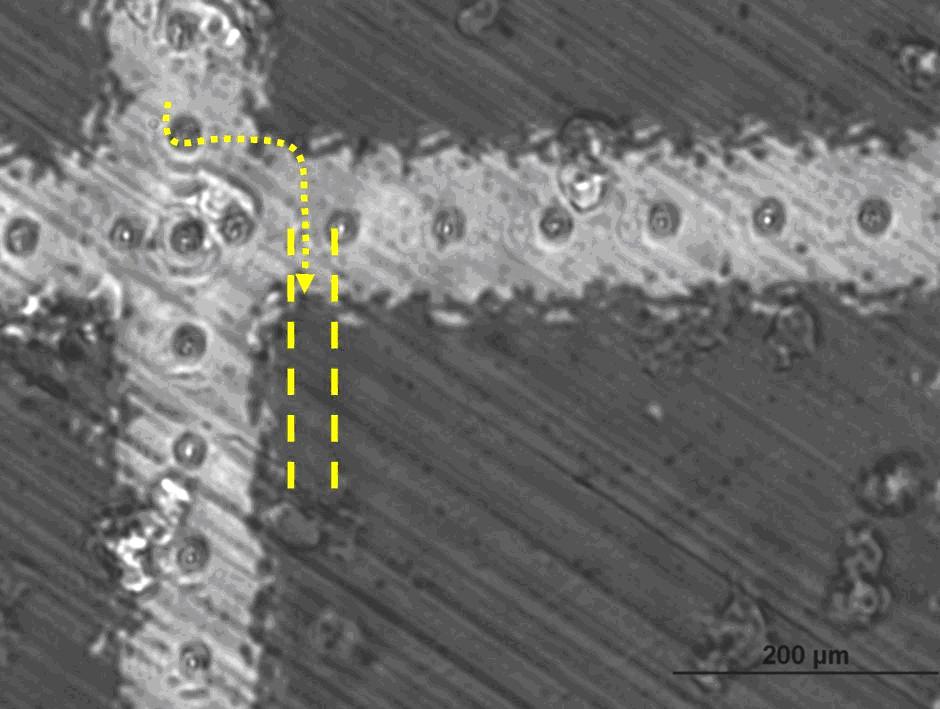

The bio-physical examinations are performed in static conditions with different cell lines, namely, from Dictyostelium discoideum as a model organism to fibroblasts as well as using blood. The materials are also subjected to the dynamical test to observe the cell detachment kinetics. For a given cell, the detachment occurs for the critical stress values, caused by the applied hydrodynamic pressure above a threshold, which depends on the cell size and the physicochemical properties of the substrate. The tests revealed differences in behaviour, depending on the applied coating material. To observe changes in the cell viability and morphology after cell material interactions (attachment), it is applied a confocal scanning microscopy (CSM) which is the sophisticated type of the fluorescent microscopy where the light source is laser (Fig.4). Even with continued advances in endovascular technology, surgical replacement of the disfunctional vessel by autologous grafts or synthetic prostheses remains the key therapy. Novel vascular grafts which provide higher patience rates, are therefore urgently required. In recent years, new techniques have been developed to apply micro- and nanoarchitecture designs mimicking the three-dimensional morphology of the vessel wall, including bioactive surface structuring and in-vitro-manufacturing of cell-formations and tissue-engineered grafts (Fig.5,6). Using these new available technologies, the research activity is performed in two main directions at IMIM PAN: (i) Nanoscaled functionalization of porous scaffold biomaterials for cardiovascular prostheses, (ii) Nanostructural materials for implants and cardiovascular biomedical devices. The studies on the blood contacting materials is dealing with participation in national and international projects, like: Polish Arificial Heart, CardioBioMat (Nanostructural materials for implants and cardiovascular biomedical devices MNT Era-Net) and NanoSurfScaffolds (Nanoscale surface functionalization of porous surfaces MNT Era-Net), in the field of advanced designs of implantable heart prosthesis and cardiovascular devices, as well as in the search of modern technologies of materials sciences (Fig.7). This is realized in cooperation with Polish and foreign research institutions, like Austria, France. International cooperation realized by the IMIM PAN between the highly reputable key research groups and industrial partners is of a special need in this multidisciplinary activity (materials science - biochemistry - medicine) to achieve an improvement in treatment for patients in the shortest possible time.

The subject of the research examinations carried out at IMIM is also dealing with structural analysis of hydroxyapatite materials (of natural and synthetic origin), i.e. component of natural bones with respect to their biocompatibility and bioactivity. Hydroxyapatite powders are processed to take a form in which they can find an application in health care i.e. dense hydroxyapatite bioceramics and porous hydroxyapatite bioceramics. Morphology of samples is characterized with respect to their influence on in vitro biocompatibility. The scope of research covers culture of stabilized cell lines of the osteoblast type on the surface of tested materials and incubation tests in a simulated body fluid (SBF). It is expected that the research will allow the preparation of bone implants of good mechanical properties as well as a good biocompatibility and bioactivity. An influence of morphology and topography of samples on their interactions with biological material is going to be assessed. The research activity realized at IMIM concerns the problems of materials science at the intersection of engineering and medicine dealing with the material surface characterization and the cell-material interaction.

Biomaterials (pdf file - 1,2MB)

back